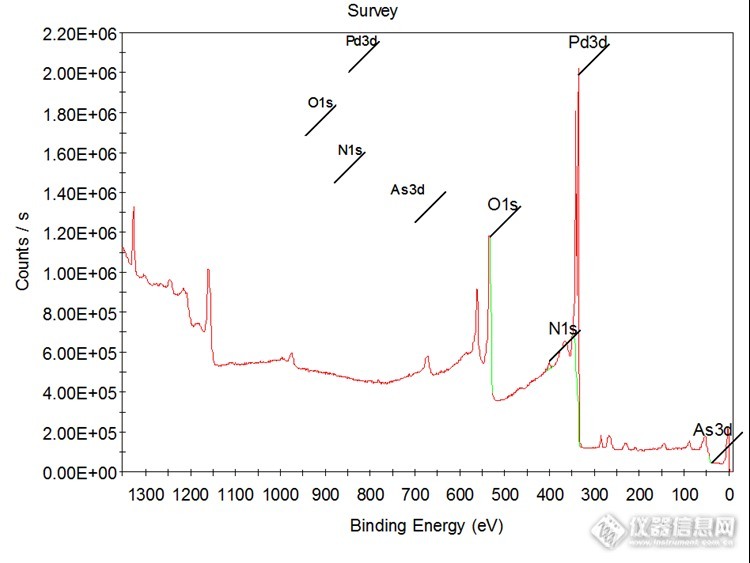

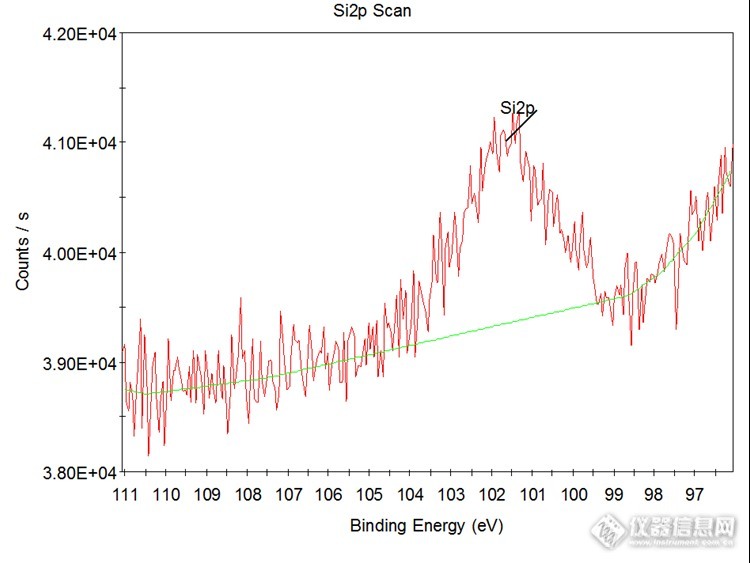

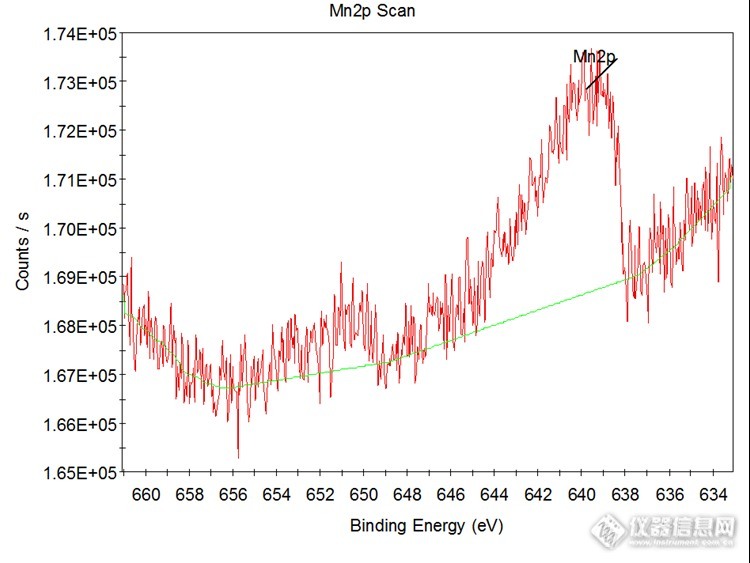

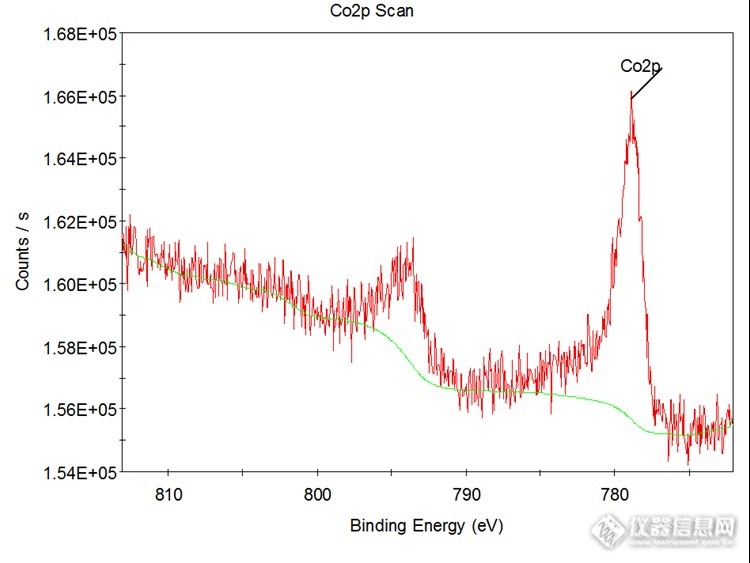

如我的样品是Co2MnSi,(表面概率2nm左右的Pd保护层 ,他们说不打掉不影响结果)扫描后得到了这四幅图

1.suvey中对应区域放大的图形形状和对应的scan扫描图一样吗?(如Mn的2p电子结合能为640-650左右那么对survey600-700区域放大的图与Mn的scan图一样吗)

2.survey图的cps为什么比scan的大好多(对比相同横坐标区间)

3.我这个样品的扫描图像是好还是不好?根据这个结果得到的原子比可靠吗?

4.为什么扫描图像(尤其是Mn和Si)毛刺那么多,且主峰很宽

5.发过来的数据中atomic的相对比是按什么方法计算的

6.表面的Pd保护层对测试有大影响吗

因为是第一次测XPS,所以问题比较多,希望论坛的各位前辈解答一下,谢谢大

![]()

![]()

![]()

![]()

家了!!!!!!

家了!!!!!!

家了!!!!!!