液压成型模拟和高压试验系统

在汽车和航空制造技术飞速发展的今天,复杂的整体及部件构形除了要求高强度、高韧性、质量轻的金属材料以外,更期冀先进的成型工艺,使工程师的设计成为现实;先进的发动机技术也有赖于压力管路及喷油系统能够持续不断的在高压下稳定可靠的工作。用尖端的数字化电液伺服控制技术,为提高工业品质量、为改善人们的生活素质作出了卓越贡献。

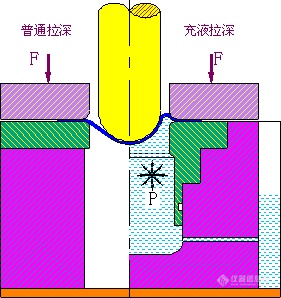

液压成型模拟和高压试验系统在高精度、全数字闭环控制电液伺服液压控制领域.它向科研、产品开发、生产制造、质量控制等领域提供了高科技的产品及技术服务。它的产品包括,液压成型模拟系统及各种附件、高压泄漏试验系统、液压胀形模拟系统及软件建模、液压胀形生产系统及模具开发、热气成型系统、伺服控制精密液压冲压系统等。

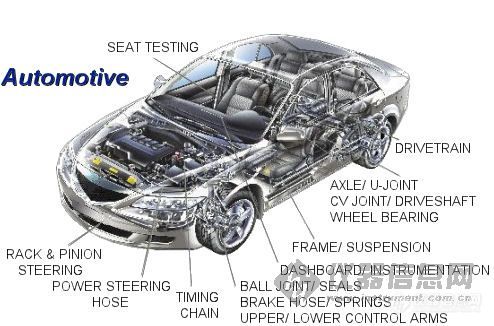

液压成型模拟和高压试验系统的用户遍及众多行业,包括:钢铁、金属加工、金属制品、汽车、航空航天及各高等院校和相关科研机构。它的领先技术提供了更准确、可靠的试验数据,使研究者缩短了研发进程,协助用户生产出高性价比、高质量的产品使工厂生产出了高质量的产品。

![]() 液压成型模拟和高压试验系统

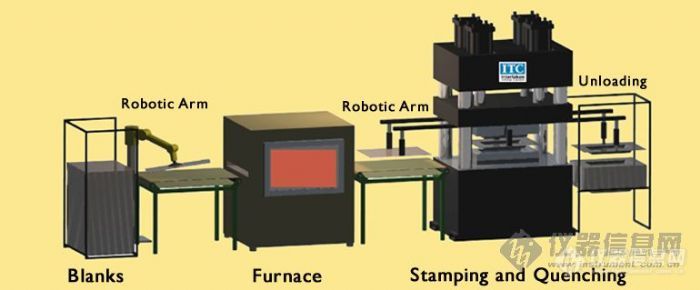

液压成型模拟和高压试验系统Interlaken Hot Stamping Press Systems are ideal for producing light-weight, high strength parts with precise dimensional accuracy.

The hot stamping process involves heating a blank or a preformed part in a furnace to approximately 950 C. To avoid significant heat loss, the heated blank is then quicly transferred into the Interlaken press for forming. A controlled press hardening or “quenching” process is then performed. The Interlaken hot stamping press allows manufacturers to produce high strenght, complex shapes and geometries in materials without material springback. With an Interlaken hot stamping press, manufacturers will have the confidence and quality assurance to produce stronger, lighter, higher accuracy parts at volume for a reasonable price.

The Hot Stamping Process

The entire hot stamping process.....from a sheet blank to finished product.

Step 1. Boron coated steel blanks or preformed parts are fed into a furnace on a conveyor belt.

Step 2. The steel blanks or preforms are evenly heated in the furnace to austenitic temperature, 950 degrees C (1,700 degrees F).

Step 3. One hot steel blank or preform is removed by a robotic arm to be quickly positioned into the die for forming.

Step 4. The part is formed by the hydraulic press at a precise forming pressure.

Step 5. A uniform quenching or hardening cooling process takes place while the hydraulic press dwells for a few seconds. Because the part is rapidly cooled in the die while the press is dwelling, springback is minimal.

Step 6. The finished part is removed by an unloading robot for part cleaning, secondary operations, or quality control.

![]()

![]()

![]()

![]()

液压成型模拟和高压试验系统Interlaken Hot Stamping Press Systems are ideal for producing light-weight, high strength parts with precise dimensional accuracy.

液压成型模拟和高压试验系统Interlaken Hot Stamping Press Systems are ideal for producing light-weight, high strength parts with precise dimensional accuracy.