The Purity and Cleaning of Plastics

Contamination issues with plastic containers, although less severe than other container types, are critical.

"The determination of trace elements at very low levels, particularly in liquid samples, has been found to be biased by the analytical blank and can often be attributed in large part to contamination from sampling and storage containers."1

Conventional sample handling methods were compared to clean techniques for individual 35 steps. These steps covered sample collection, storage, preparation and measurement of water samples for Ag, Cd, Cu and Pb. It was reported that two thirds of all steps contributed statistically significant amounts of contamination in the measurement of dissolved and particulate Cd, Cu, and Pb -- the average contamination for a single contributing step was 300% (Cd), 141% (Cu), and 200% (Pb).2

This section includes a closer look at part of a plastic container materials study conducted by Inorganic Ventures' technical staff3. Areas of interest in this study included the following:

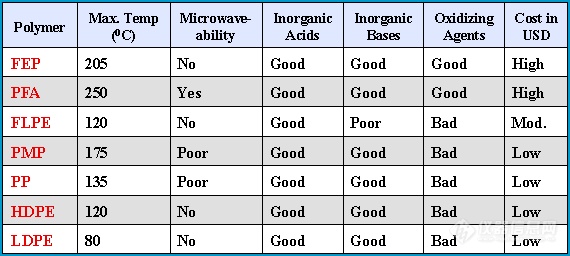

Availability and price (see Table 5.1)

Chemical resistance (see Table 5.1)

Physical properties (including transpiration) (see Table 5.1 - transpiration data presented Part VI)

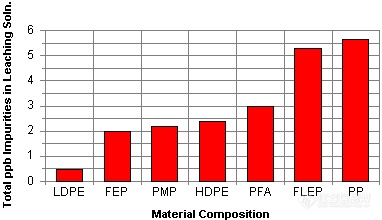

Identify (+) contaminants

Determine (+) contaminants level

Effectively remove (+) contaminants

Identify (-) contamination (adsorption)

The plastics chosen for this study are shown above in Table 5.1. Results of this study will be cited to illustrate points throughout this chapter. This section will address the identity, level, and removal of contaminants in these plastics.

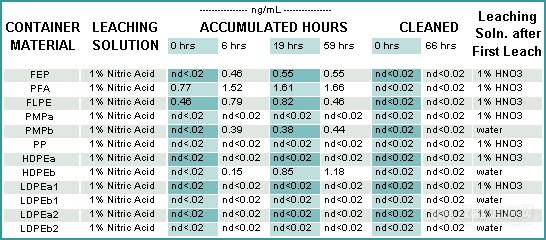

- Experimental Design -

All containers were filled and handled in a clean area.

"Conductivity" water and doubly distilled nitric acid were used.

All leaching was performed in an oven at 60 °C.

All measurements were made using an

ICP-MS, located in a clean room.

The leachate solution was measured directly from the container under study.

Leaching solutions were exposed only to the container under study.

Leaching solutions were only exposed to ULPA filtered air.